The Rise of Custom Mold Factories in China: A Comprehensive Guide

In the realm of manufacturing, there is a significant emphasis on precision, quality, and efficiency. Amongst the leaders in this field are China custom mold factories, renowned for their advanced capabilities in producing plastic molds and injection molded products. This article explores the intricate world of mold manufacturing in China, delving into the processes, benefits, and innovative approaches that these factories employ.

Understanding Custom Mold Manufacturing

Custom mold manufacturing refers to the process of designing and creating molds that are tailored specifically to the requirements of a product. This is especially crucial in industries where precision and custom fit are paramount. The process typically involves several stages, including:

- Design Phase: Utilizing computer-aided design (CAD) software to create detailed mold designs.

- Prototyping: Creating prototypes to test the design and functionality of the mold.

- Production: Utilizing state-of-the-art machinery to manufacture the mold.

- Testing: Conducting rigorous tests to ensure quality and precision before full production.

This meticulous approach ensures that the molds produced meet stringent industry standards and customer specifications.

The Advantages of Choosing China as Your Custom Mold Factory

When it comes to selecting a custom mold factory, many businesses look towards China due to a variety of compelling reasons:

1. Cost Efficiency

China offers competitive pricing for manufacturing due to lower labor costs and economies of scale. Companies like Hanking Mould leverage this affordability to provide high-quality molds at lower prices compared to other countries.

2. Skilled Workforce

The expertise found within the Chinese manufacturing workforce is unmatched. Many engineers and technicians in this realm have extensive training and experience in mold design and production techniques. This wealth of knowledge contributes to efficient processes and superior products.

3. Advanced Technology

China is at the forefront of adopting advanced molding technologies. Factories are equipped with the latest machinery, including high-speed machining centers and accurate CNC equipment, which enhance production speeds and the precision of molds.

4. Quick Turnaround Times

In today’s fast-paced market, time is critical. Chinese mold factories are capable of rapid prototyping and fast production cycles, ensuring that businesses can launch products quicker than ever.

The Mold Manufacturing Process: A Deep Dive

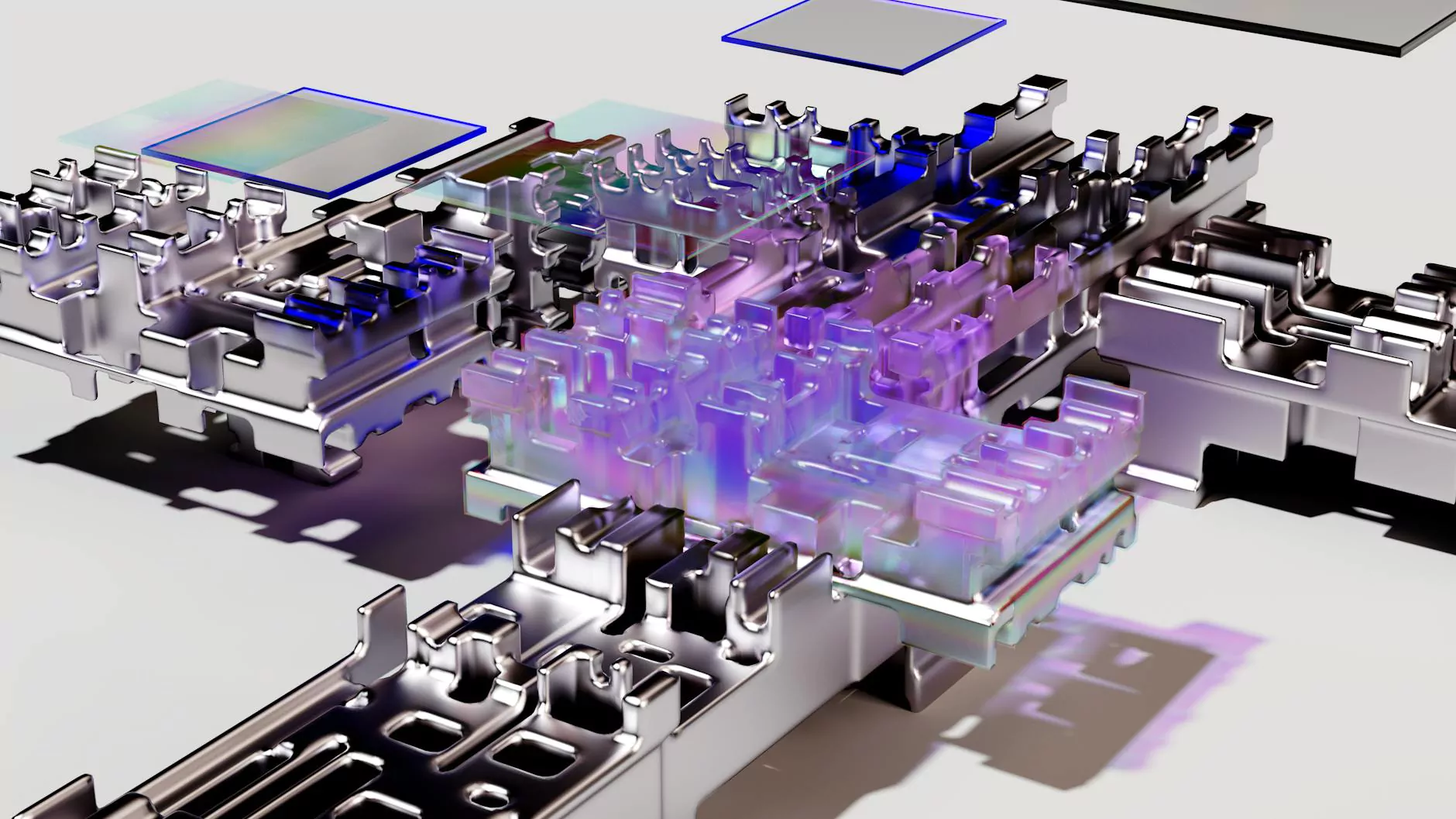

The mold manufacturing process consists of several key stages that transform raw design concepts into functional molds ready for production:

Step 1: Mold Design

The first step in the process is the design of the mold, which is often carried out using CAD software. This digital approach allows for precise calculations and adjustments. Key design considerations include:

- Mold Type: Determining if the mold will be single or multi-cavity.

- Material Selection: Choosing suitable materials based on the final product's requirements.

- Cooling System Design: Planning for effective cooling channels to improve cycle times.

Step 2: Prototype Development

Once the design is finalized, a prototype of the mold is created. This prototype allows for testing and validation of design specifications. Changes can be made before moving to full-scale production, significantly reducing errors and costs.

Step 3: Manufacturing the Mold

The actual manufacturing of the mold involves several processes:

- CNC Machining: Utilizing CNC machines for precision cutting and shaping of mold components.

- EDM: Electrical discharge machining is often used for intricate details and hard metals.

- Assembly: Once all parts are produced, they are carefully assembled into a complete mold.

Step 4: Testing the Mold

Before mass production can begin, the mold undergoes rigorous testing. This step is essential to ensure that it functions correctly and produces high-quality products. Tests include:

- Dimensional Inspection: Confirming that all dimensions meet specifications.

- Trial Runs: Executing production trials to identify any issues with the mold.

Types of Molds Offered by Chinese Factories

Chinese custom mold factories are capable of producing a variety of molds, catering to different industries and applications:

1. Plastic Injection Molds

These molds are designed for producing plastic parts through injection molding techniques. They are highly versatile and used across various industries, including automotive, electronics, and consumer goods.

2. Blow Molds

Blow molding is utilized for hollow plastic products, such as bottles and containers. The design of blow molds is crucial for ensuring the strength and durability of the final product.

3. Compression Molds

These molds are typically used for thermosetting plastics and rubber. Compression molds require careful design to manage the flow of material and achieve uniform thicknesses.

4. Die Casting Molds

Used primarily for metals, die casting molds are essential for producing high-quality metal components. These molds are designed to withstand high pressures and temperatures.

Choosing the Right China Custom Mold Factory

When selecting a China custom mold factory, several factors should be taken into consideration to ensure the partnership is beneficial:

1. Experience and Reputation

Researching the factory’s experience and reputation in the industry is vital. Look for testimonials and case studies that showcase their successful projects.

2. Quality Assurance Processes

Ensure that the factory implements strict quality control measures throughout the manufacturing process. Certification such as ISO 9001 indicates a commitment to quality.

3. Communication and Support

Effective communication is crucial for a successful partnership. Ensure the factory has a dedicated team available for updates and support throughout the project.

4. Research and Development Capabilities

Factories with strong R&D departments can provide more innovative solutions and alternatives to meet specific project needs.

The Future of Custom Mold Manufacturing in China

The future of custom mold manufacturing in China is poised for growth. As industries evolve, factories are expected to adopt even more sophisticated technologies such as artificial intelligence and automation, enhancing efficiency and cutting costs further. Sustainable practices are also gaining prominence, prompting factories to adopt eco-friendly materials and processes.

Conclusion

In conclusion, China custom mold factories represent a pinnacle of excellence in the manufacturing industry, providing high-quality, efficient, and cost-effective solutions for plastic mold making and injection molding. By understanding the processes and advantages of partnering with these manufacturing leaders, businesses can better position themselves in a competitive market. Whether you are looking for superior molds or innovative solutions tailored to your specific needs, China’s custom mold factories stand ready to deliver, ensuring their role as trusted partners in the journey of production.

Explore more about how Hanking Mould, a leading factory in this domain, can meet your custom mold needs and help propel your business forward in today's challenging market landscape.